MSS Case June: Two crew members burned by hot water

The incident arose during the repair of a valve connected to a 12-inch pipeline that ran from the auxiliary boiler in the engine room to the main deck, used for heating the cargo warming coils. The repair was initiated after condensation was observed, leading the Chief Officer to suspect a faulty valve, even though the valve and heating system were not routinely used.

The Chief Engineer assigned the Second Engineer to carry out the repair. At approximately 10:00 AM, the Second Engineer conducted a toolbox meeting with the involved crew, detailing the steps: shutting down the auxiliary boiler, draining the pipeline of water, and blanking the line at a

flange near the boiler before commencing any work on the valve. During this meeting, the Fitter and the Motorman expressed concerns that this was a non-routine task more suitable for dry-dock conditions, but their objections were overruled and the job proceeded as planned.

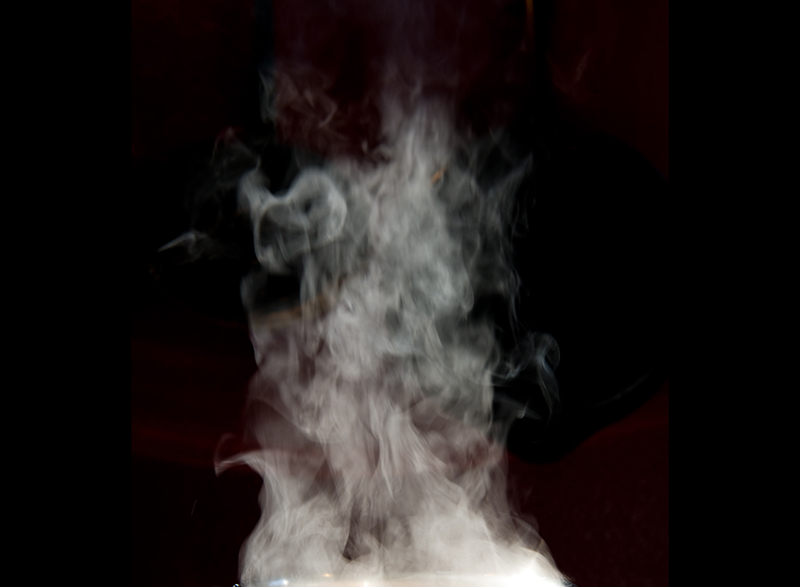

The boiler was shut down, the line drained, and the blank installed before the crew took a lunch break. After lunch, the Fitter and Motorman positioned themselves beneath the valve to remove its bonnet cover. They had removed two nuts and partially loosened two others when a sudden

discharge of hot water—estimated between twenty and thirty litres—occurred. Because the workspace beneath the valve was confined to about one meter in width, the two men could not evade the surge of water. Both sustained burns to their legs, arms, back, buttocks, and portions of their faces. Although two other crew members in the vicinity received minor splashes and were treated with first aid onboard, the injuries to the Fitter and Motorman were more severe.

The Master arranged for the immediate evacuation of the injured men from the anchorage. They were transferred by launch from the vessel to shore and then taken to a specialized burn treatment facility at a local hospital. The following day a Marine Investigator and a legal

representative, along with three port state inspectors, boarded the vessel to investigate. During interviews with the Master, Chief Engineer, and involved crew, it emerged that there was no written procedure in the vessel’s Safety Management System (SMS) for this kind of maintenance.

Both the Master and Chief Engineer acknowledged the lack of formal guidelines and agreed that, going forward, more extensive personal protective equipment would be employed and additional cooling times instituted before undertaking similar work.

The Port State Inspector’s examination of the site revealed that caution tape now marked the valve area. They concluded their onboard inquiry and recommended prompt valve repair. Medical personnel indicated that while both crew members suffered first- and second-degree burns over a significant portion of their bodies, the burns were not deep, and treatment prognosis was favourable. They should be able to return to work.

Questions

When discussing this case please consider that the

actions taken at the time made sense for all involved. Do

not only judge but also ask why you think these actions

were taken and could this happen on your vessel?

- Does our SMS address these risks?

- What sections of our SMS would have been

breached if any? - How can we improve our toolbox meetings and

communication so that crew members feel

comfortable raising concerns, especially for nonroutine

jobs? - What additional steps can we take to ensure that

equipment is fully cooled, isolated, and safe to

work on before maintenance begins? - In what ways can we enhance our PPE standards

to match the specific hazards of each task, such

as working with hot fluids under pressure?

- How can we ensure that all crew members,

including engineers and deck crew, receive

continuous training on hazard recognition, risk

assessment, and proper emergency response? - What communication channels can we

strengthen to make certain that safety concerns

raised during toolbox meetings are properly

evaluated and escalated if necessary? - How should we follow up after an incident to

confirm that corrective actions (such as updated

procedures, improved PPE, and training) have

been implemented and are effective? - How can we encourage a proactive safety culture

where lessons learned from past incidents—both

onboard and from industry sources—are regularly

reviewed, discussed, and incorporated into daily

operations? - What immediate, actionable steps can we take

from today’s discussion?

MSS Case June: Two crew members burned by hot water

An incident during a non-routine valve repair led to the sudden release of hot water, severely burning two crew members. Despite safety concerns raised beforehand, the job proceeded without a written procedure in place.

For more Loss Prevention information, please contact:

Joakim Enström, Loss Prevention Officer

E-mail: joakim.enstrom@swedishclub.com

Each month, the Club’s Loss Prevention team issues a new safety scenario to assist members in their efforts to comply with international safety regulations and follow best practices.